Call us: 07971189546

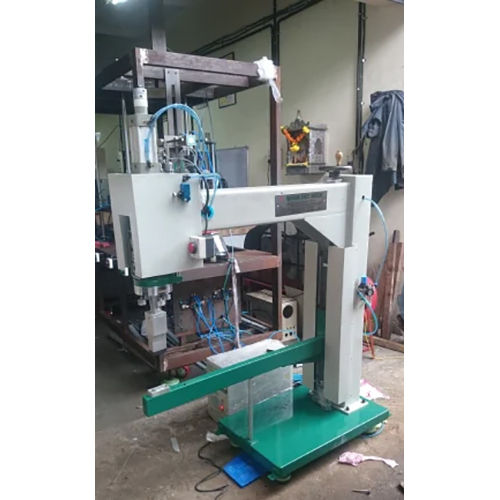

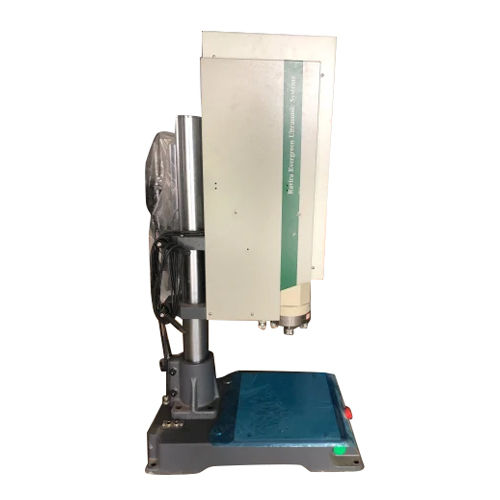

With excellence in business, we manufacture the best-in-class Rotary Table Plastic Welder Machines, Box Welder Machines, Surgical Sewing Machines, Label Cutting Machines, and more.

HOT PRODUCTS

MOST POPULAR PRODUCTS

Ultrasonic plastic welding technology is a state-of-the-art welding method utilized for joining thermoplastic parts or automotive components by applying high-frequency vibration. This technology helps to attain homogeneous joint quality without any contamination. Mumbai, Maharashtra (India)-based Ravira Evergreen Ultrasonic Systems Pvt. Ltd. started its operation in 2006 with an aim to utilize this technology to improve welding performance by offering a wide range of ultrasonic plastic welding equipment and other industrial machines.

As a prestigious manufacturer and supplier, this organization is involved in offering a meticulously designed range of products that include Surgical Sewing Machines, Rotary Table Plastic Welder Machines, Label Cutting Machines, Box Welder Machines, etc., to name a few. The provided welding machinery is appreciated for its high output rate, smooth operation, long working life, required safety features, and ease of handling. With a well-equipped production house, this company is expanding its business opportunities under the guidance of Mr. Mahendra (the director). At present, this company possesses one branch to execute all the stages of its operation in a systematic manner.

Quality Assurance

Quality signifies the success of any organization in terms of its products or services. Proper management of quality is essential for any company in order to differentiate itself from its competitors. With a decade of domain knowledge, we have adopted a strict quality-checking policy to ensure the unmatched quality of each of our products. Advanced methodologies are followed to determine the flawlessness of the series of equipment that we offer. The whole product range is verified on the basis of its welding speed, energy consumption, productivity, mechanism, user-friendliness, and maintenance features.

Infrastructure

Ravira Evergreen Ultrasonic Systems Pvt. Ltd. possesses a well-furnished production unit that employs around 25 competent employees for producing an extensive range of machinery that blends perfection with pioneering technology. This production unit has been developed with the objective of providing the top manufacturing facilities to our hard-working employees in order to motivate them to produce an impeccable range of Label Cutting Machines, Rotary Table Plastic Welder Machines, Surgical Sewing Machines, Box Welder Machines, etc. This manufacturing section contains high-end machinery like polishing equipment, cutting machines, lathe machinery, drilling machines, moulding machines, CAD machinery, machines for determining amplitude, frequency analyzers, weld trial equipment, special purpose machinery, and more.

Why Choose Us?

We believe that we possess several attributes for which our business associates and customers desire to be a part of our business endeavor. These attributes include:

- We have a strong infrastructure.

- Organized and experienced team of professionals.

- Wide distribution network.

- Customer-oriented business approach

- Emphasis on maintaining the quality of offered products.

- Cost-effectiveness and high efficiency of products

- Honest business policy

- On-time product delivery system.